Bautechnik

Baustofftechnologie

Bauwerksinstandhaltung

Wer sind wir?

Als Spezialdienstleister im Bereich der Bauwerksinstandsetzung, Baustofftechnologie, Schadensdiagnostik und Qualitätssicherung hat sich die

LPI Ingenieurgesellschaft mbH seit der Gründung im Jahr 2004 bundesweit einen Namen gemacht. Mittlerweile sind wir deutschlandweit führend im Bereich der Bauwerksinstandsetzung.

Unser qualifiziertes Team mit über 180 Mitarbeiter*innen realisiert für Sie und Ihr Projekt maßgeschneiderte Dienstleistungen in den Bereichen Prüfung und Inspektion, Bauplanung, Bauüberwachung und Baumanagement, Beratung und Begutachtung, Bauwerksmonitoring sowie unserem Spezialbereich LPI Green, der nachhaltiges Planen und Bauen im Fokus hat.

Was macht uns aus?

Wir mögen es unkompliziert.

Daher haben wir es uns zum Ziel gemacht, auch komplexe und anspruchsvolle Fragestellungen möglichst einfachen und praxisorientierten Lösungen zuzuführen.

Wir legen großen Wert auf Qualität.

Diese steht bei uns immer im Einklang mit dem wirtschaftlichen und reibungslosen Ablauf in der Projektausführung.

Wir setzen auf unser Team.

Denn gerade die Qualifikation und Erfahrung unserer Mitarbeiter*innen ist maßgeblich für die professionelle Durchführung Ihres Projekts und zeigt sich auch immer wieder in der persönlichen und direkten Betreuung während der Zusammenarbeit.

Wo gibt es uns?

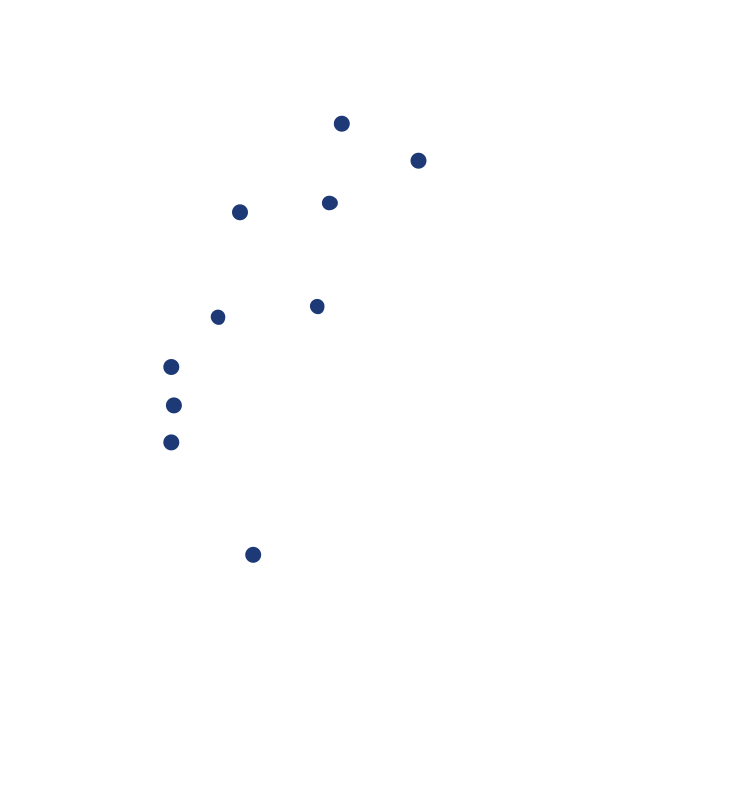

Seit LPI 2004 im heutigen Hauptstandort Hannover mit der Arbeit begann, sind wir stark gewachsen. Mittlerweile betreuen wir Sie von insgesamt zehn Standorten in ganz Deutschland aus – ob hoch im Norden von Wismar bis Kiel, Hamburg und Westerstede, über die Mitte der Republik von Hannover bis Herten, Osnabrück, Wuppertal und Köln, bis hin in den Süden in Darmstadt: Uns gibt es immer und überall ganz in Ihrer Nähe.

Ihr Bauwerk ist unsere Profession

AKTUELLES

Deutschlandweit

Ihr Persönlicher Ansprechparnter

Ganz egal, wie komplex Ihr Projekt auch ist, wir sind schnell für Sie da – dank kurzer Wege zu Ihnen von unseren 10 Standorten in ganz Deutschland. Kompetent, persönlich und mit allen Leistungen aus einer Hand.